In March 2025, Japan’s West Japan Railway Company (JR West) achieved a groundbreaking feat by constructing a 3D-printed train station in a mere six hours. This pioneering endeavor took place at Hatsushima Station in Arida City, Wakayama Prefecture, replacing a 75-year-old wooden structure that had succumbed to the ravages of time. This article delves into the intricate details of this project, exploring the motivations, design, construction process, advantages, challenges, and broader implications of utilizing 3D printing technology in railway infrastructure.

Background and Motivation

Japan’s rural railway stations have faced significant challenges in recent years, primarily due to declining populations and constrained budgets. Many of these stations, constructed decades ago, have deteriorated, necessitating innovative solutions for refurbishment and maintenance.

Hatsushima Station, located on the Kisei Line, exemplified this trend. The original wooden building, serving the community for over seven decades, required replacement to ensure safety and functionality.

JR West, grappling with reduced passenger numbers and an aging workforce, sought a cost-effective, efficient, and durable solution. The adoption of 3D printing technology emerged as a promising approach to address these challenges.

Design and Collaboration

The project was a collaborative effort between JR West and Serendix, a Japanese firm specializing in 3D-printed structures. The design aimed to blend modern construction techniques with local cultural elements.

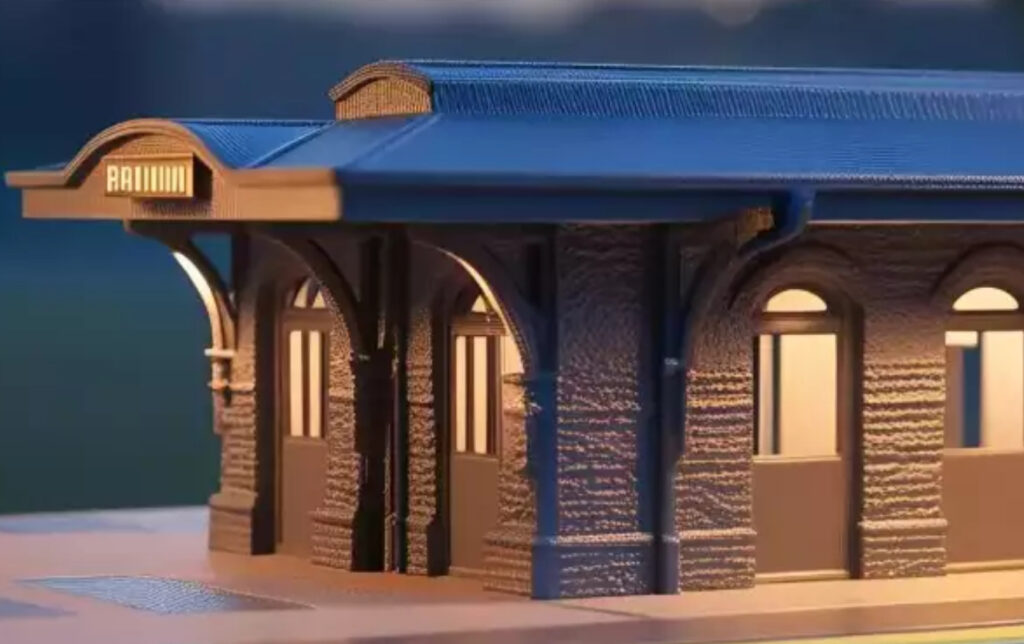

The resulting structure is a single-story building measuring approximately 2.6 meters in height and covering an area of about 10 square meters. Notably, the exterior features decorative reliefs of a mandarin orange and a beltfish, both local specialties of Arida City, symbolizing the region’s heritage.

Construction Process

The construction process involved several meticulously planned steps:

- Prefabrication of Components: Utilizing advanced 3D printing technology, Serendix produced the building’s components off-site. The formwork was created using mortar, into which reinforcing steel was inserted, and then filled with concrete to ensure structural integrity and earthquake resistance comparable to traditional reinforced concrete structures.

- Transportation to Site: The prefabricated components were transported to Hatsushima Station during off-peak hours to minimize disruption to regular train services. This logistical planning was crucial to adhere to the tight construction schedule.

- On-Site Assembly: The assembly was scheduled between the last train of the day and the first train of the following morning, a window of approximately six hours. Using cranes and a coordinated team of workers, the components were assembled efficiently, completing the structural framework within the allotted time.

- Finishing Touches: Following the structural assembly, interior elements such as ticket machines and lighting were installed. Once these installations were finalized, the old wooden building was demolished, marking the completion of the transition.

Advantages of 3D Printing Technology

The application of 3D printing technology in constructing Hatsushima Station offered several notable benefits:

- Rapid Construction: Traditional construction methods for a station of similar scale typically require around two months. The 3D printing approach reduced this timeframe to just six hours for on-site assembly, significantly minimizing service disruptions.

- Cost Efficiency: The project was completed at approximately half the cost of conventional reinforced concrete construction, offering substantial financial savings.

- Design Flexibility: 3D printing allowed for the incorporation of unique design elements, such as the decorative reliefs representing local culture, enhancing aesthetic appeal and community connection.

- Structural Integrity: The use of reinforced concrete ensures durability and resistance to environmental factors, including seismic activity, which is crucial in earthquake-prone regions like Japan.

Challenges and Considerations

While the project showcased the potential of 3D printing in infrastructure development, it also highlighted certain challenges:

- Scale Limitations: The current application was for a relatively small structure. Scaling this technology for larger stations or complex buildings may present additional challenges in terms of printing and assembly logistics.

- Material Constraints: The selection of appropriate materials that balance printability, strength, and durability remains a critical consideration for broader applications.

- Regulatory Compliance: Ensuring that 3D-printed structures meet all safety and building regulations is essential, necessitating ongoing collaboration with regulatory bodies.

Broader Implications and Future Prospects

The successful implementation at Hatsushima Station serves as a proof of concept for the broader application of 3D printing technology in public infrastructure. For regions facing similar challenges of aging infrastructure, labor shortages, and budget constraints, this approach offers a viable solution. JR West has indicated plans to evaluate the cost-effectiveness and maintenance requirements of the 3D-printed station, with the potential to replicate this model in other locations.

Furthermore, this project underscores the importance of integrating modern technology with cultural considerations, demonstrating that infrastructure can be both functional and reflective of local heritage.

No comments yet.